Ensuring the Durability and Longevity of Defence Standard Cables

Installing and maintaining Defence Standard Cables is an important aspect of ensuring the reliability and longevity of the Cable.

From pre installation, to the ongoing maintenance, adhering to best practices is essential.

We will look at the installation and maintenance of Defence Standard Cables, to maximise durability and the cables’ lifespan.

Planning Stages:

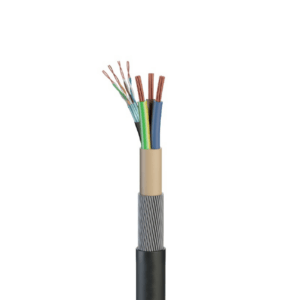

Cable Selection:

– Identify the specific requirements of the installation, consider factors such as:

- Voltage.

- Signal type.

- Environment.

– Choose a Defence Standard Cable that meets or exceeds the necessary specifications for the intended application.

Cable Size:

– Determine the appropriate cable size, based on the specific requirements and potential environment.

– Consider future expansion needs to avoid the need for cable replacement.

Installation Route and Conditions:

– Plan the cable route with careful consideration of the installation environment.

– Avoid areas prone to excessive heat, moisture, or mechanical stress.

– Account for potential interference from other cables or electronic equipment.

Installation Techniques:

Watertight Connections:

– For outdoor installations, use weather-resistant and watertight connectors to prevent moisture damage.

– Apply appropriate sealants and insulating materials to ensure the longevity of connections.

Secure Mounting:

– Install cable supports and secure fasteners to prevent stress on the cables.

– Use proper clamps and brackets to secure cables in place, especially in areas with vibrations or movement.

Avoid Sharp Bends:

– Minimise the use of sharp bends during installation to prevent damage to the cable’s insulation.

– Follow recommended bend radius guidelines for the specific cable type.

Inspection and Maintenance:

Regular Inspections:

– Routine inspections to check for signs of wear, damage, or environmental degradation.

– Inspect connectors, joints, and termination points for tightness and security.

Preventive Maintenance:

– Implement preventive measures, such as applying corrosion-resistant coatings to connectors.

– Conduct regular testing of cable integrity using appropriate equipment.

– Keep records of maintenance activities for future reference.

Corrective Maintenance:

– Address any issues identified during inspections to prevent further damage to the cable.

– Replace damaged or compromised cables, connectors, or insulation.

In Summary:

Installing and maintaining defence standard cables requires planning and regular attention to their condition.

Defence Cables can operate with reduced risks of failures by:

- Choosing the right cables.

- Planning the installation route.

- Conducting regular inspections.

These best practices contribute to the overall durability and longevity of Defence Standard Cables.

If you have more questions, feel free to contact our friendly team. We’re always happy to help!