Guides & Tips

An Overview of Fire Cables

- Fire detection.

- Fire alarms.

- Fire suppression systems.

- Emergency escape lighting systems.

- (and aim to have:) Security cameras and video links.

What Does A Fire Alarm Cable Do?

Fire cables are intended to work during a fire and not fail in the case of high temperatures being applied to them. These cables are providing power and data to alarm sounders and visual fire signals to guarantee that individuals in all regions of the building may safely leave.What Cable is Used for a Fire Alarm?

Any cable that is compliant with British Standard BS 5839-1, which addresses the operation of fire protection systems, such as:- Smoke control.

- Emergency lighting.

- Automatic door

- Fire alarm systems.

- Voice alarm systems.

- Fire extinguishing systems.

- Elevator grounding.

- Valve closing.

- or Air handling shutdowns.

Does a Fire Alarm Cable Have to be Red?

No, the fire alarm wire that is compliant in BS 5839-1 does not have to be red, but it must be a distinct colour from other forms of electrical wiring within the building. Although, it is an industry norm to not alter the colour of the fire alarm wires. If a different cable colour is utilised, the customer should agree on a variation as part of the design before installation.What is the Difference Between Fire-Rated and Fire-Resistant Cable?

Flame Rated or Flame Retardant refers to cables that do not continue to work during a fire but are meant to prevent flame spread, propagation, smoke evolution, acidic/corrosive gas evolution, and burning droplets. Fire Resistant cables are those that are meant to offer continuous power/signal supply for safety installations while also preventing the passage of fire for a certain period.What is an Enhanced Fire Cable?

All cables are intended to guarantee that the connectivity between fire alarm systems functions properly for an acceptable amount of time. The BS 5389-1 cable standard distinguishes between ‘Standard’ and ‘Enhanced’ grade cables, which define the amount of fire resistance that the cables provide. Enhanced: The ‘Enhanced’ grade is intended for usage in situations where the fire detection and alarm systems need to enable evacuation for a longer period than the ‘Standard’ grade fire-resistant cables provide during a fire. Standard: In addition to meeting the requirements of BS 5839-1, Standard fire performance cables must obtain a class of at least PH30 when tested in line with EN 50200. They must also keep the circuit running. Additionally, enhanced fire-resistant cables are recommended for the following applications:- In un-sprinkled buildings (or areas) when the fire plan calls for occupant evacuation in four or more stages.

- Buildings that are taller than 30 metres that are not sprinkled.

- In un-sprinkled premises and sites where a fire in one place may harm vital signal route cables associated with areas remote from the fire, and where it is anticipated that humans may stay in occupancy during the fire.

- In any situation where the designer, specifier, or regulatory body believes that the use of Enhanced fire-resistant cables is needed based on a fire risk assessment.

Does a Fire Alarm Cable Need to be in Conduit?

To minimise mechanical damage, you should aim to not include fire alarm wires in the same conduit as other utility cables. There are instances where fire alarm cables may be put in the same conduit as other service cables, however; a separate compartment should be created specifically for the fire alarm wires. The trunking partition should be sturdy, stiff, and continuous. The guideline is designed to prevent harm to the fire alarm cables when other circuits are modified (for example, when other cables are stripped out or new cables are drawn in.) It may not always be practical to provide a separate conduit, trunking, or compartment for fire alarm wires in some situations, such as when installing a new fire alarm system in an existing but old structure. In such circumstances, a deviation from the standard’s guidelines should be indicated in the system’s certification. Where cable segregation is not reasonably possible, care must be taken to prevent electromagnetic interference from other cables from disrupting the fire alarm circuits.

Best Budget Speaker Cable

Best Speaker Cable

The most popular and utilised cables are made from copper, considering copper is a great conductor of electricity. Our recommendation for a budget speaker cable is that you opt for a wire that is copper-plated or copper-clad aluminium if you are on a budget, as they are both good substitutes for the wire composed entirely of copper. But before you choose a cable, there are a few aspects to be considered such as the quality of your sound system and the budget you have. If you have a hi-fi system, it may be worth investing in an Oxygen free copper cable to ensure the greatest quality wire. These types of cable use polyethylene insulation instead of the traditional PVC one. They suit oxygen free copper conductor ideally.Types of Speaker Conductors

It is commonly accepted that different conductor materials have distinct sound characteristics, despite the fact that there are no discernible changes in how these materials measure in terms of frequency response. By definition, frequency response is a rudimentary metric that cannot quantify all audible, interactive, and idiosyncratic non-linearities and other features.- Copper – the most common type, it sounds warmer and has more body, but it is slower and less harmonically rich

- Silver-plated copper – exceptionally good at carrying musical information precisely across a wide frequency range but it is a more costly option; sounds livelier and harmonically rich, but with a colder character and lighter and thinner body

- Pure Silver – used in professional environment

- Pure Gold – used in professional environment

Relationship Between Conductors and Insulation

This is a critical area because pairing the wrong sort of insulation with the wrong type of conductor can result in a speaker cable acting like a tone control and bringing plenty of undesired colourations into the music you listen to. The issue with these colourations is that they might emphasise specific frequency ranges, affecting degrees of apparent detail and, more importantly, the coherence and timing of a piece of music.Conclusion

Choosing a speaker cable for your sound system depends on the type of system that you have and for what purpose you use it. If it is in a more professional environment, we recommend you invest in more costly materials. However, that does not guarantee that there will be a sound improvement if your sound equipment does not already have the range to achieve it.

Braiding vs Screening vs Shielding

Shielding or Screening?

Shielding and screening are the same! They are both a protective layer added over the conductors to protect the cable from, or prevent it from causing, electrical interference. Disturbance can cause lower quality signal or data loss and can therefore result in equipment failure, therefore it is essential to choose the right screening for the right purpose. Shielding and screening come in many different forms, each with a specific purpose.Types of Shielding

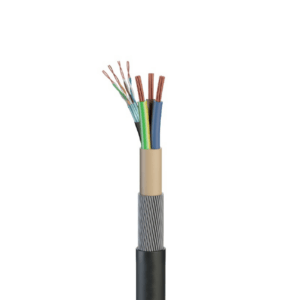

Braiding

Braiding is when cables are woven in a lattice of thin tin or copper wire, looking like a braid as the name suggests. The coverage of the braid (often referred to as the density) depends on the number of strands or wires within each plait. It also depends on the thickness of the braid strands. The diameter of the braid wires also specifies the level of damage the cable can withstand. Braiding is used for mechanical protection against any electrical or electromagnetic interference, as well as to add strength to the cable. Braiding is usually applied either over the inner sheath if there is one, or directly over the core bundle. Braiding can be applied in different materials for very specific purposes:- Copper – used for screening against electromagnetic interference

- Steel – used for mechanical protection

- Glass or Ceramic fibres – used for high temperature environments

- Rayon – used for torsional strength

Foiling

Foil screening involves wrapping the cable cores in aluminium or polyester laminated tape to increase durability. The foils must be in contact with a bare wire to act as an earthing point. Foil shielding can offer up to 100% coverage and can withstand high-frequency applications. It’s also quick, cost-effective and easy to produce due to its lightweight nature. However it is slightly less durable than traditional braiding, so it is not recommended to use foil shielding in areas where a lot of flex is needed.Armouring

Armouring is not a form of screening, but it is a common method of protection for cables. It is often constructed by winding galvanised steel wires over the cable in the form of a spiral. Armouring is often used when cables are to be laid in an outside environment – it prevents vermin and termites from attacking and damaging the cable. Though armoured cable can be less flexible and harder to terminate, there is no better way to protect a cable from this sort of interference. For more information about cable screening, get in touch with our friendly team, or shop our wide range of cables today.

Can Coaxial Cables be Used for Power?

Can I Use A Coaxial Cable for Power?

While coaxial cables are most often used for carrying video signals, you might be surprised to learn that it’s a common practice in the engineering industry to also use them to power small-scale electronics. Coaxial cables feature high-quality shielding and insulation to ensure a reduction in signal loss outside the cable, so can be an ideal choice if you’re particularly concerned about signal loss. However, the reason why this isn’t standard practice is because coaxial cables can be more expensive than other cables that can be used in the same application. There are also coaxial cables that feature a shotgun style construction, meaning that there are two connected cables sold as a pair. One cable is an RG cable, and the other is a power cable – this way, if you’re looking to power a video system, one cable will power the video system, and the other will carry the video signal.What Other Cables Can Be Used for Power?

The types of cable that are ordinarily used for power are simply referred to as power cables. They are used to transmit electrical power from one location to another. There are a few different types of power cables – to view our helpful guide on the types of power cable, click here. If you’re looking for a power cable for an application where it’ll be moved around once installed, we recommend Flexible Power Cables. These are constructed specifically to withstand the daily wear and tear that a cable undergoes if constantly flexed or moved around; for example, a regular Power Cable may experience breaks in the shielding, insulation, or even the sheathing if flexed too much. If you have any questions that weren’t answered in this article, please click here to contact our team of experts.Belden Equivalent Cables

Explore Our Cables

TV Satellite Coaxial Cables

Our range of TV coaxial cable has been conformity certified by the CAI and independently tested by RN Electronics, ensuring that it is of the highest quality. These coaxial cables are used to carry video signals or radio frequencies and are often used to connect a TV set to either a TV aerial or satellite receiver.

Explore our TV Satellite Cable range

Defence Standard Cables

Defence standard cable is used to connect electronic equipment in aircraft, data processors, and military equipment. Originally manufactured for use in the military and defence industries, as the name suggests, defence standard cable is now used in a wide variety of industries and applications such as control systems, computers and alarm systems.

Explore our Defence Standard Cable range

Data Cables

Data cable is designed for use in computer systems, allowing data transmission between multiple machines over a single network. It can also be used for Power Over Ethernet (POE) applications. We offer a wide range of data cabling that perform at different transmission speeds to suit a variety of applications.

Explore our Data Cable range

Reasons to buy from Securi-Flex®

Cut to length service

1000m Lengths Available

Award Winning Cables

About Us

Established in 1998, Securi-Flex® is considered one of the leading cable suppliers in our industry, specialising in the importation and distribution of specialist cables, accessories and cable handling products to the Electrical Wholesale and Security Distribution market. We supply our cable & accessory products across the UK, Ireland, and Europe, supporting the recognised industry buying groups including AIEW, ANEW, AWEBB, FEGIME, IBA, and MIDA. We are also official affiliated members of the EDA (Electrical Distributors Association). Securi-Flex® is an industry leading brand and supplier – we pride ourselves on our products and service, and understand that in a competitive market, we need to differentiate. We believe that choosing the right supplier partner is vital for the success of your supply chain and customer satisfaction, and at Securi-Flex® we recognise that our values, product, and service is an extension of your brand and business.