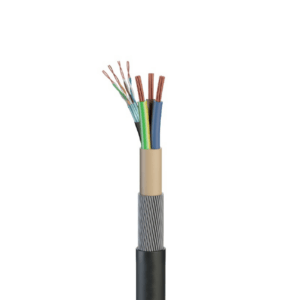

In the majority of cases, the electrical cabling around your home or business will contain pure copper, or at least mostly copper wire.

The properties of these cables can vary due to the sheathing or insulation used, but cables can also perform differently when their cores are made from alternative metals.

Here are some of the most common core materials available.

Pure Metal Cores

Copper

Copper is one of the highest standard materials used for electrical conductors. Although not quite as conductive as silver, copper is a far more economical and widely supplied material, making it the standard for most cabling applications.

Sometimes, copper can be hard to solder unless a ‘flux’ is used – this is a compound used in the soldering process that cleans the surface in preparation for bonding. Using a flux can result in corrosive residues being left behind, so in some cases, copper will be tinned or plated to avoid this – see more about copper-clad cables below.

Pure copper, however, is the gold standard of conduction and is suited for pressure terminations too. Copper is also incredibly malleable and can be bent into any shape or direction – although the sheathing material used can have limitations on this ability.

Aluminium

Aluminium is favoured for cable conductors due to its lightweight nature. It is slightly less conductive than copper, but when balancing this with its weight, performs on a similar level.

Aluminium is also relatively inexpensive, but cannot be soldered easily, so is often plated with copper to gain the benefits of both materials in a single wire.

Silver

Silver is an incredibly good conductor, better than copper in fact. It is, however, substantially more expensive. Silver-plated wire is more common, as it utilises the conductive benefits of silver and allows the wire to operate over a wide temperature range (from -65°C to 200°C).

There are a few niche uses where silver’s extremely low resistance is a key element – scientific instruments and cryogenics may utilise pure silver conductors for this reason.

Gold

Gold is a common form of plating for brass connector pins – though it’s not that commonly used for cables due to the expense of the materials.

Easily soldered, gold has good corrosion resistance. It’s not as good a conductor as copper and silver, but resists oxidation far better, which is why it is used as a plated layer to protect some inner components.

Tinned Cable

Tin is generally not used on its own as a cable conductor, but is used as corrosion protection for copper without affecting its conductivity. Coating a copper cable in tin can also make it far easier to solder.

Nickel-Plated

Nickel-plated wire also operates in extreme conditions over a wide temperature range. If the nickel-plating is thick, it can withstand temperatures up to 750°C. Nickel also acts as an excellent layer of corrosion resistance.

Metal Clad Cores

Copper Clad Aluminium

Copper clad aluminium cable is aluminium cable plated in copper. This makes the cable less expensive than pure copper, but lighter too, as aluminium in itself is an incredibly lightweight material.

However, CCA cable allows the aluminium element to gain more electrical conductivity when combining this with copper, as well as adding to the strength of pure aluminium.

Copper Clad Steel

Copper clad steel is comprised of a steel wire plated with copper. As copper is more expensive than steel, it allows the cable to combine the benefits of both materials for a lower price.

CCS cable is not quite as conductive as pure copper, but this level of conductivity is not needed in every application. Copper clad steel wire has double the mechanical strength of solid copper wire, giving it longevity in harsher environments and under frequent movement.

For more information about our range of cables, get in touch with our friendly team.